Ma Valves a Mpira Wonse wa Port: Mfundo Zopangira, Mawerengedwe, ndi Ntchito Zamakampani

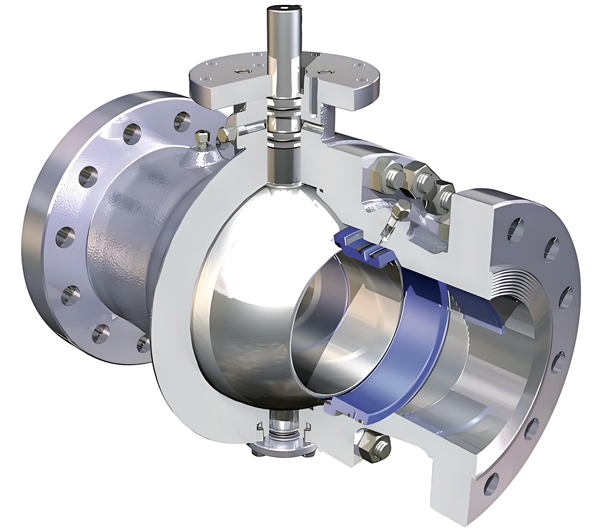

Chidutswa cha njira yoyendera ma valve a mpira ndi chinthu chofunikira kwambiri pakugwira ntchito.mavavu athunthu a mpira, gawo ili limasonyeza momwe kayendedwe ka madzi kakuyendera bwino, kutayika kwa mphamvu, komanso kuyenerera kwa mafakitale omwe amafunidwa kwambiri. Umu ndi momwe mungapangire ndikuzigwiritsa ntchito bwino.

Valavu Yonse ya Mpira wa Port: Tanthauzo & Njira Zowerengera

1. Tanthauzo Lalikulu

Valavu ya mpira yokhala ndi doko lonse (yodzaza ndi chitoliro) ili ndi m'mimba mwake wa njira yoyendera madzi yofanana ndi ≥95% ya m'mimba mwake wa mkati mwa payipi, zomwe zimathandiza kuti madzi aziyenda bwino popanda kupanikizika kwambiri.

2. Kuwerengera Kochokera pa Mayendedwe

Gwiritsani ntchito njira yogwiritsira ntchito mphamvu ya madzimadzi:

Q = K × Cv × √ΔP

Q: Kuchuluka kwa madzi (GPM kapena m³/h)

K: Chinthu chowongolera (nthawi zambiri 0.9)

Cv: Kuchuluka kwa madzi (kwa valavu)

ΔP: Kusiyana kwa kuthamanga (psi kapena bala)

Fomula yochokera pa bore diameter:

d = (Q / (0.9 × Cv × √ΔP)) × 25.4

(d = m'mimba mwake mu mm; 25.4 = kusintha kwa inchi-mm)

3. Njira Yachidule Yochepetsera Kukula kwa Paipi

d = D × 0.8

d: M'mimba mwake wa valavu

D: M'mimba mwake wakunja wa payipi

Chitsanzo: Pa chitoliro cha OD cha 100mm, sankhani valavu yokhala ndi bore ya ≥80mm.

Doko Lonse vs Doko LochepetsaKusiyana Kofunika Kwambiri

Chizindikiro | Vavu Yonse ya Mpira wa Port | Kuchepetsa Valavu ya Mpira wa Port |

|---|---|---|

| Njira Yoyendera | Chiphaso cha chitoliro chofanana (monga, DN50 = 50mm) | Masayizi 1-2 ocheperako (monga, DN50 ≈ 38mm) |

| Kugwira Ntchito Moyenera | Kukana pafupifupi zero; kuyenda kwathunthu | Kuchepetsa kwa madzi ndi 15-30% |

| Kutsika kwa Kupanikizika | Zosafunika | Zofunika kwambiri pa kuchuluka kwa madzi |

| Mapulogalamu | Chofunika kwambiri pa kusamba nkhumba, madzi okhuthala | Machitidwe oyenda pang'onopang'ono; mapulojekiti owononga ndalama zambiri |

Chidziwitso Chofunika:

Valavu ya DN50 yodzaza ndi madoko imasunga kuyenda kwa 50mm, pomwe valavu ya DN50 yocheperako imachepetsa kuyenda kwa madzi kufika pa ~DN40 (38mm) - kutayika kwa malo oyenda ndi 24%.

Ntchito Zamakampani: Kumene Ma Valves Athunthu a Madoko Excel

1. Mapaipi a Mafuta ndi Gasi

Ntchito:Kutseka/kulamulira mzere wa trunk

Ubwino:Zimathandiza kuti mapaipi azikonzedwa bwino; zimathandiza kuti mafuta osakonzedwa/matope asatsekeke.

2. Kukonza Mankhwala

Nkhani Yogwiritsira Ntchito:Mizere yodyetsa ya reactor yothamanga kwambiri

Phindu:Zimaletsa zoletsa kuyenda kwa madzi zomwe zimasokoneza kupitiriza kwa kupanga.

3. Kasamalidwe ka Madzi

Mapulogalamu:

1. Mapaipi amadzi a boma

2. Malo olowera/kutulukira kwa malo oyeretsera madzi otayira

Chifukwa: Zimathandizira kuti pakhale kuchuluka kwa nthawi yomwe anthu ambiri amafuna zinthu zambiri.

Malangizo Osankha: Nthawi Yosankha Doko Lonse

Sankhani ma valve odzaza ndi ma port ngati:

1.Kuyenda n'kofunika kwambiri:Machitidwe omwe amafuna kutayika kochepa kwa mphamvu (monga mapaipi akutali).

2. Nkhani ndi zovuta: Madzi okhuthala, matope, kapena makina oyeretsera.

3. Kuteteza mtsogoloMapulojekiti omwe akuyembekezera kuchuluka kwa kayendedwe ka madzi.

Kuganizira za Mtengo:

Ma valve odzaza ndi ma port amtengo wapatali ndi 20-30% kuposa kuchepetsa ma port koma amachepetsa kugwiritsa ntchito mphamvu ndi 15% m'makina oyenda kwambiri.

Nthawi yotumizira: Feb-15-2025